Piezoelectric Device Manufacturing Process

The manufacturing process are explained on the following websites;

Equipment Required for Piezoelectric Device Manufacturing

We have the following equipment to manufacture the Piezoelectric Device from the Piezoelectric powder;

| Sr. No. | Equipment | Picture | Model & Make |

| 1 | Dry Powder Pressing Dies |

|

Custom Made dry-powder pressing dies manufactured from D2 steel, surface hardening and extra fine mirror-like polishing surfaces. We have the Disc shape dies of diameter [60mm, 36mm, 30mm, 12mm]We have Ring shape dies of [12mm OD, 6mm ID] |

| 2 | Hydraulic Press-1 |  |

Universal Testing Machine, 50kN (5.0 Ton), Hydraulic, Model TM 115, ESSOM Company Limited. Location: Strength of Material Lab, DME, CEME |

| 3 | Hydraulic Press-2 | ||

| 4 | Hydraulic Press-3 | ||

| 5 | Furnace for Binder Burn-out (BBO) |

|

Model No. (RHTMF-1/18) Make: PCSIR, Pakistan. Specifications: Temp Range: Ambient to 1200°C ±1°C, Control: Digital Temp control, Muffle Size: 100 x 112 x 220 mm, Capacity 2.6 L, Operating Voltage: 220V – 50Hz. |

| 6 | Tube Furnace for Sintering |  |

Make: PCSIR Pakistan, Model: Sintering Tube Furnace, Temperature 1400C. Location: research Lab, DME, CEME |

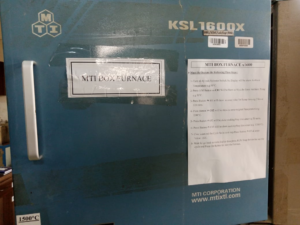

| 7 | Box Furnace for Sintering |  |

Make: MTI, Model: KSL 1600X, Temperature 1500C. Location: Heat treatment Lab, SCME Datsheet: Link |

| 8 | Polishing and Grinding Machine |

|

Make: Metkon Model: Forcipol 2V Grinder polisher, Location: research lab, DME, CEME Datasheet: Link |

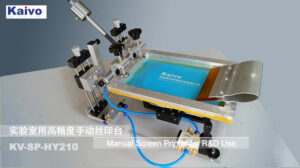

| 9 | Electrode Paste Screen-Printing Machine |  |

Manual Screen Printer for R&D Use. Model: KV-SP-HY210, Make: Kaivo, Zhuhai Kaivo Optoelectronic Technology co Ltd, china Datasheet: Link Location: Micro and Nano Robotics Technologies Lab, DMTS, CEME |

| 10 | Polling Machine with High voltage DC Power Supply |  |

Make: MTI, Model: , Tempertaure 10KV High Voltage DC Power Supply, with High-Viscosity Silicon Oil Heating Tank and Piezo Fixture. Model: IPS-ATDP1000-1.2 1000VDC 1.2A 1200W DC High Voltage DC Power Supply Company: IDEALPLUSING TECHNOLOGY, Guangdong Yibenyuan Power Supply Equipment Co., Ltd. China Location: Micro and Nano Robotics Technologies Lab, DMTS, CEME |

1. Shape and Resonance Frequency of the required Piezoelectric Ceramic

First, select either a required dimension or resonance frequency of the PZT material. Resonance frequency depends on the vibration mode (Radial, thickness, shear etc.), the dimensions (radius or thickness), and material properties of the PZT material. Then using an online calculator (APC International , CTS Ferroperm ), verify the following three things;

- Piezoelectric Material Type (PZT-4, PZT-8, PZT-5 etc.)

- Shape of the end Piezoelectric Transducer (Disc, Ring, Plate, Cylinder etc.)

- Resonance Frequency of the Piezoelectric (Radial/Length/Transverse, Thickness in Fundamental vibration mode)

2. Pressing of the Ceramic Powder in the Dry Powder Pressing Die

The details of the Piezoelectric dry powder pressing are available at

- American Piezo (Pressing PZT Powders)

- SubsTech (Basic Terminologies of Dry Pressing)

First, find the Dry Powder Pressing Dies, some options are

- Pressing dies by MTI Cooperation

- Zhengzhou TCH Instrument Co., Ltd. (Alibaba Store)

- Zhengzhou TCH Instrument Co., Ltd. China

- Pellet Press Die Set (PPDS), USA

Some Videos illustrating the Dry pressing process are;

- Morgan Process Animations – Die Pressing on Youtube

- How to Use a Laboratory Pellet Press Die Set – MSE Supplies on Youtube

- Small 10 mm I.D. Dry Pellet Pressing Die For Hi-throughput Pressing – EQ-Die-10S – Youtube Video

- Split-able Dry Pressing Die 20 I.D.x 100H(mm) – EQ-Die-SP20 – Youtube Video

- Customized Splittable Dry Pressing Die for Ring Type Sample – Die-Ring-C – Youtube Video

- Compaction in Powder Metallurgy production processes – Youtube Video

Now we need to calculate the quantity/weight/mass of the piezoelectric powder to be poured in the pressing die. As the diameters (outer only for disc shape, inner and outer both for ring shape) is fixed by the die design. Only the thickness of the pressed die can be changed by varying the quantity of the piezo powder. The goal is to achieve the approximate density of 4.75gm/cm3 while pressing. Density (volumetric mass density or specific mass) is a substance’s mass per unit of volume. where ρ is the density, m is the mass, and V is the volume. The total reduction of Piezo manufactured device from the pressed sample after sintering will be from 15-20%. Calculate the required mass by choosing a thickness, as density should be 4.75gm/cm3, cross sectional area is also known.

Measure the Piezo powder weight on a precision weighting device. After filling the die in a uniform and consistent way, with no particles on side walls, initiate the press stroke. Approximately 10,000 PSI (68.94 Newton/square-milli-meter) is required to achieve the 2:1 compaction and ~4.75 g/cm3 desired green density of pressed pellet. Therefore, we can calculate the force required to be inserted on the die in Hydraulic-press to achieve the required ~4.75 g/cm3 density and volume. A 30mm diameter disc Piezo has cross-sectional area of 707mm2, requiring 48.8kN/mm2 of pressure (4.88 Ton force on Hydraulic Press).

To reduce these friction forces while pressing in the compaction stroke of Uniaxial Pressing, a lubricant may be added to the powder prior to pressing. Wax like stearates are among the most commonly used lubricants for dry pressing, since small additions can reduce ejection force by 50% or more. Lubricants (wax, magnesium stearate, stearic acid) reduce the interfacial frictional forces between individual particles favourable to powder compaction and/or between particles and die surfaces. They also reduce the required ejection pressure of the compact, thus avoiding macro-defect formation. Those additives will be eliminated by thermal decomposition before sintering or in a special zone of a continuous sintering furnace.

The article below are recommended to be read before the dry powder pressing process

- F. Lemoisson, L. Froyen, 12 – Understanding and improving powder metallurgical processes, Editor(s): Seshadri Seetharaman, In Woodhead Publishing Series in Metals and Surface Engineering, Fundamentals of Metallurgy, Woodhead Publishing, 2005, Pages 471-502, ISBN 9781855739277, https://doi.org/10.1533/9781845690946.2.471. https://www.sciencedirect.com/science/article/pii/B9781855739277500121